ColorMaster

Expert system for recipe management and color measurement

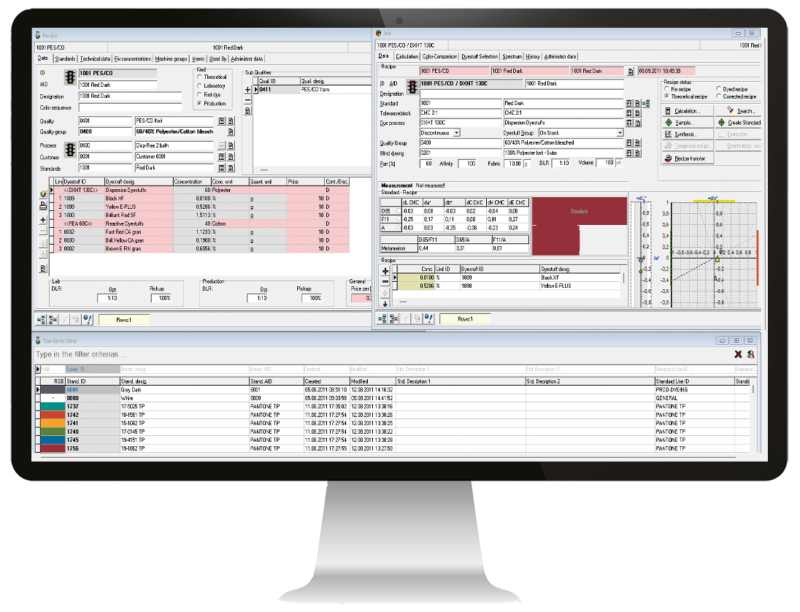

The Windows-based software package ColorMaster is an expert system for recipe management and color measurement. In the laboratory the system allows the best and most cost-effective recipe to be calculated. For production, the integrated processes within ColorMaster offer the best possible treatment and define the correct dye program. Colorimetric control for the different production steps and calculations of additions with addition treatments enhance the functionality of the system. To create a dye house with completely optimized automatic production, ColorMaster is, together with the management system SedoMaster, a powerful and necessary tool.

ColorMaster is a modular system that can be set up for a simple recipe and quality control system or to a complete system with production management. All modules are connected to the same database. It can be easily adapted according to the needs of new requirements.

Modules

- Production

- Color measurement

- Link to SedoMaster

- Link to laboratory dosing station

- Database access

Impressions

Optimized production, integrated color and recipe management

Process and recipes

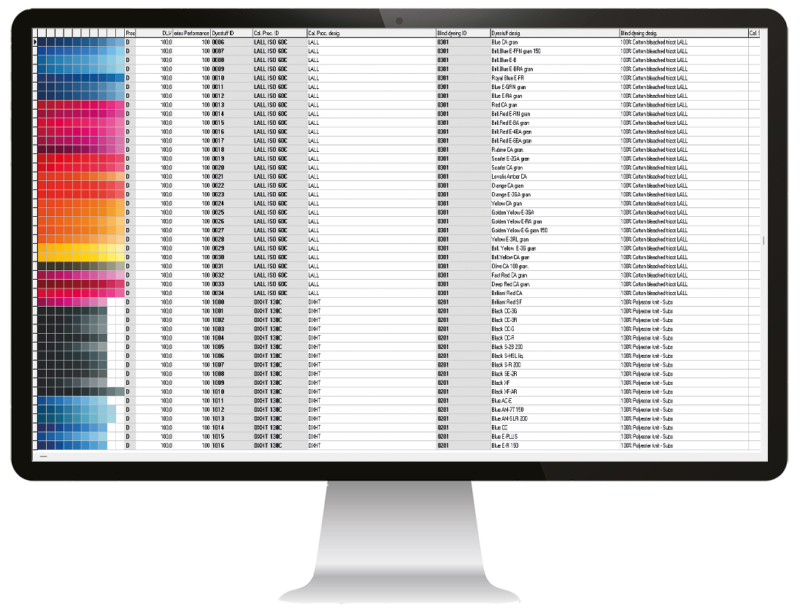

ColorMaster can create intelligent production processes for all finishing types, mapping all production machines, used materials and different treatment routes. The control and administration of the entire finishing area can be developed into three logical groups.

Definitions DEF: Customers, suppliers, machine groups and the machines with key features such as minimal and maximum liquor are defined here. Type of distribution, weighing and dosing systems and all data of a connected production management system describe the production possibilities.

Process Management PM: Dyestuffs and their classes, chemicals, parameters, and the process material based on fiber types are determined here. The dyestuffs to be used in the production recipes are selected in the dye processes.

Production PROD: Recipes are based on an individual treatment. These are divided into production and laboratory treatments. A treatment (e. g., bleaching, dyeing, soaping and rinsing) consists of a sequence that describes the preparations, chemicals, dyestuffs, gradients (parameter) and manual instructions for the machine operator. Using rules treatments, chemicals, parameters, and dyestuff requirements are calculated for production.

Features

- Cost cutting in production result in optimized recipes with consistent treatments.

- Treatment safety and minimization of human errors by taking deviations from the standard process into account in production calculations.

- Environmentally friendly production by adjusting the amounts of chemicals and water for different treatments depending on the material and color depth.

- Connection to a host system is possible and color recipes of external systems can be used.

- Integrated, fully automatic production system by integration of ColorMaster into SedoMaster or another central management systems.

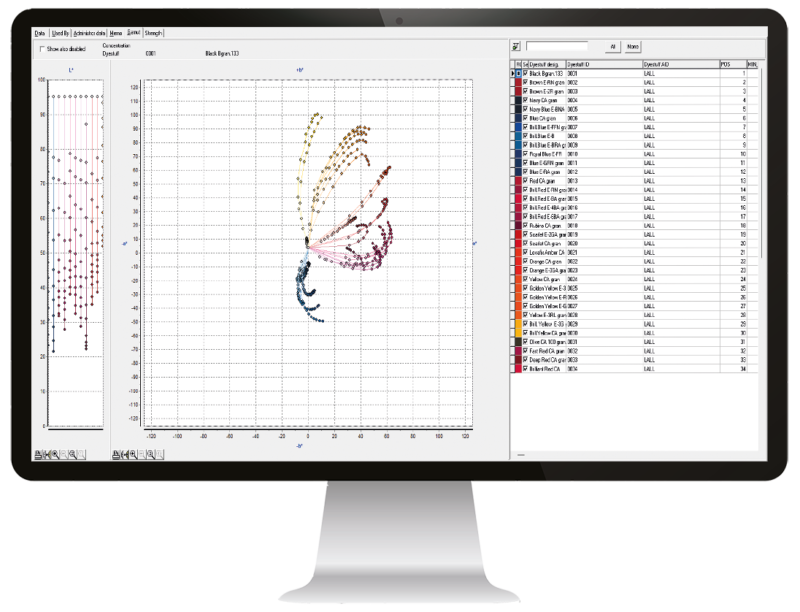

Color measurement

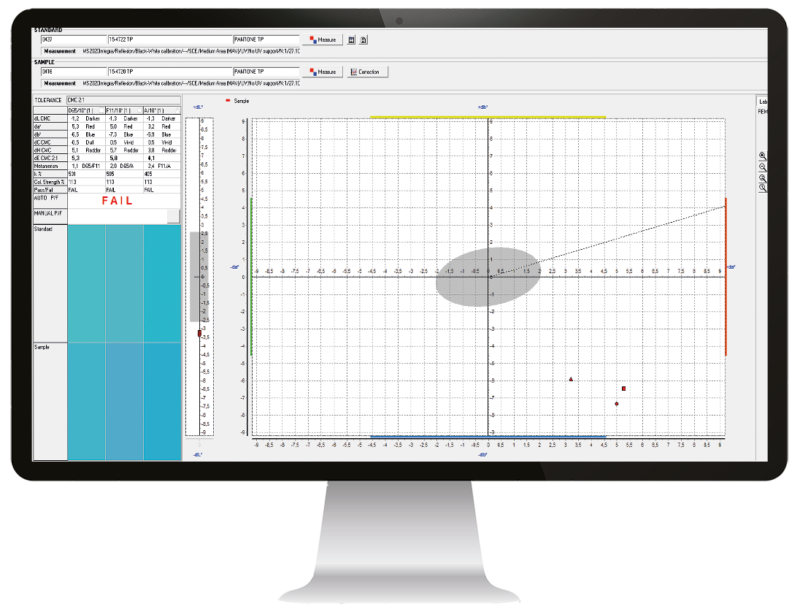

The powerful colorimetric software supports the creation of recipes for laboratory and production. A clear administration of calibration series and the corresponding dye processes simplify the efficient color development. Integrated PASS/FAIL functions with calculation of additions makes ColorMaster a true expert system for the dyeing and finishing industry.

Features

- Colorimetric search with the customer sample supports easily finding a similar production recipe. In this way laboratory work is reduced and the transfer lab/production is greatly enhanced.

- Reproducible recipes due to the further intelligent graphical laboratory applications. It ensures that the calculated recipes matches the color sample, is metamerism-free, is color consistent and inexpensive.

- Production control is supported by the integrated addition calculation. At first, recipes with different samples are prepared for Pass/Fail controls for both finishing and final inspection. Correction treatments like additions and washing treatments are stored with batch data. The dyestuff and chemical consumption is exactly registered. The report of batch data assists in recipe correction prior to a new batch and minimizes additions.

- Colorimetric reports

- Check fastness according to ISO grey scale

- Statistic evaluation

- Comparison of color strength and standard depth

- Color communication

- Whiteness according to Berger, CIE, or Ganz/Griesser