The platform for the Smart Factory

The platform for the Smart Factory

From simple machine control to the intelligent factory

From simple machine control to the intelligent factory

What is a Smart Factory?

The term Smart Factory refers to the “intelligent factory” and is a central element of Industry 4.0. The Smart Factory is part of the fourth industrial revolution and can be described as the heart of Industry 4.0 and a self-organizing production environment.

With the vision of Industry 4.0 and Smart Factory to establish digitization in industry

and manufacturing and thus both facilitate and optimize production, the following

main features and advantages become apparent.

Differentiation between IoT and IIoT

While the Internet of Things (IoT) covers a wider range of applications that are primarily aimed at end consumers, the Industrial Internet of Things (IIoT) focuses on the optimization and monitoring of industrial processes with high demands on security, data processing and reliability. Both concepts use similar technologies, but the use cases and priorities are very different. IoT is often used as a synonym for both areas.

Smart Factory as a more specific concept within the manufacturing industry, aims at the complete digitalization and integration of all production processes. It uses

IIoT technologies and many other advanced technologies to create a highly flexible and efficient production environment.

Connectivity and digitalization

When considering a smart factory, connectivity and communication are one of the main pillars. This is because with the Internet of Things (IoT), all machines, control systems, tools and devices are connected to each other via internet and can exchange data with each other in real time. Modern interface technologies ensure that all necessary functions can be seamlessly integrated into the factory systems and that bidirectional data exchange is guaranteed.

Automation

As a first step, this will bring operators closer to the goal of an intelligent factory. The integration of automation technologies throughout the entire production process represents a further step in automation. In the textile industry, Sedo Treepoint’s MES software SedoMaster smartly networks your production and makes it fit for the

Industry 4.0. As the core of digitalization, SedoMaster acts as a central information hub in production and automates machines as a software system.

No stand-alone solutions – create integrated platforms

With constantly increasing market requirements, companies are forced to improve their production and planning processes. This is the only way to ensure long-term competitiveness. For this reason, more and more companies are already relying on intelligent software solutions in production planning and control to collect and analyze large data volumes and use them to optimize production processes.

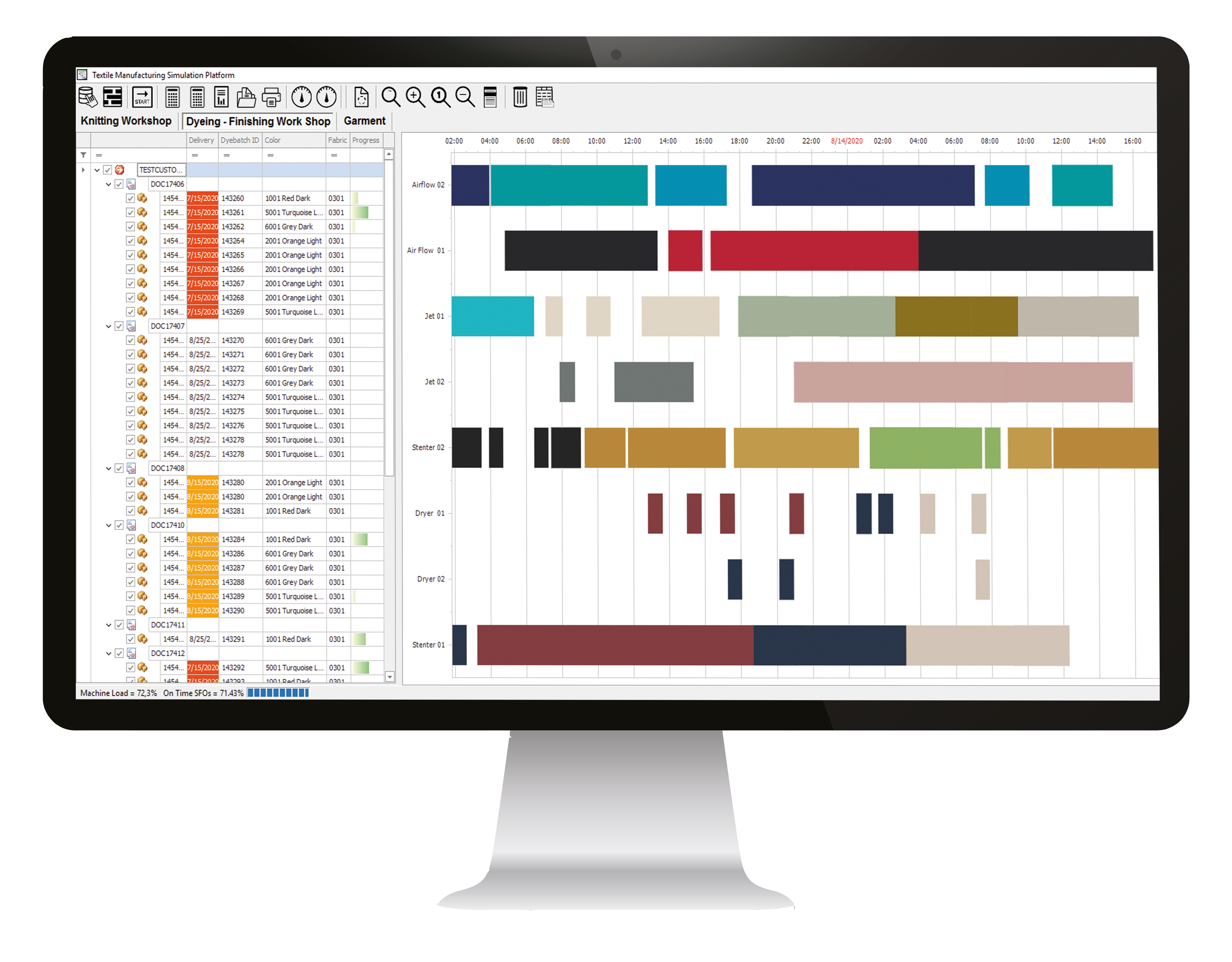

A comprehensive analysis of production data not only provides key figures, but also important information such as predictive maintenance indicators (KPIs). For example, SedoExpert and TMS support production simulation and automatic planning along your machine and production chain in order to achieve the best possible results and increase efficiency. By entering rules, information about the production batch and the machine route of the respective customer is also stored throughout the system. This creates integrated solutions in manufacturing processes that are connected instead of working separately from each other. Individual batch-based processes are therefore a part of the past.

Flexibility and customization

In the textile industry, numerous reasons make digital tools that support the production process essential: expanding product range, new processes, lack of skilled workers, increasing complexity, competitive and price pressure, rising demand for individual products, energy and sustainability requirements, circular economy and increasing regulation. Despite all the automation, rule definition, networking and communication, orders, production processes and requirements are constantly changing. Communication and automation technologies therefore must be able to implement these adaptation options and data sets reliably and efficiently.

Sedo Treepoint works with all machine manufacturers and cooperates with your system partners to create both synergy effects and benefits for your production. Wherever textiles are produced, we are there to advise you on the best possible solution. Our customers benefit from the high flexibility, efficiency and sustainability of our products to meet the requirements of demanding markets, orders and customers. Our automation technologies set a new standard with regard to Industry 4.0 and offer both the highest standards and cost-effective solutions for the transformation to a smart factory.